Understanding The Supply Chain Bullwhip Effect

December 14, 2022

The different players in the supply chain — inclu

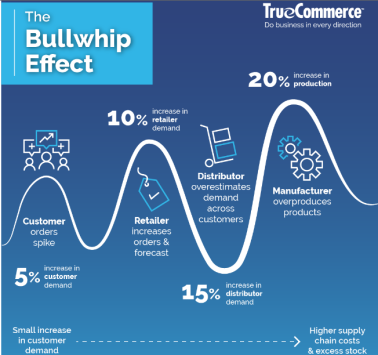

In a supply chain, the bullwhip effect occurs when each party gradually escalates an initially small spike in demand. Each member of the supply chain overcompensates for this demand with excess product, leading to increased production, inaccurate demand forecasting, and inconsistent inventories.

Fortunately, you can mitigate or prevent the supply chain bullwhip effect with the right resources and planning. Let’s look at the impact of the bullwhip effect on supply chain management and what you can do about it.

What Is the Bullwhip Effect in Supply Chain Management?

When a spike in demand occurs, each party in the supply chain adds additional products to their orders to act as a buffer. When one party does this, it serves the necessary function of ensuring in-stock products. However, when everyone does it, the result is inaccurate forecasting, stock hoarding, overstock inefficiencies, and out-of-stock products later.

Combat the bullwhip effect with integrated supply chain solutions from TrueCommerce

Example of the Bullwhip Effect in Action

-

Say a retailer sells personal heaters and normally sells an average of five units a day. As the temperatures start dropping in winter, sales spike to 15 units a day. The retailer adjusts their forecasting and orders enough stock to sell 20 units a day from their wholesaler to meet the demand.

-

The wholesaler, receiving the order for 20 items, then orders 30 units from the manufacturer.

-

The manufacturer receives the order for 30 items and increases their manufacturing run to 40 items.

A spike in demand for 15 units a day has ballooned up to 40 units, many of which won’t reach the retailer until after the demand spike is done. Manufacturing products takes time, so what happens if, while those items are being made, an early Spring appears? For the retailer, sales of personal heaters would immediately drop. The retailer’s forecasts are then affected, and they won’t order more units, even though production has increased.

Members of the supply chain can compound the bullwhip effect by hoarding stock. When items appear scarce upstream, many buyers will place large orders to buffer their inventory and stay ahead of low stock issues. This almost ensures that upstream sources will experience scarcity followed by increased production, despite only a slight change in demand. As demand moves up the chain, inventory becomes less controllable and difficult to predict, especially since many members of the supply chain don’t cooperate as well as they could.

All of this amounts to periods of both overstock and low stock and unpredictability throughout the supply chain.

Causes of the Bullwhip Effect

While the bullwhip effect starts with simple demand spikes, many elements contribute to it:

- Supply chain complexity: Global supply chains are becoming more and more complex. Consumer demands are changing, orders are more varied, and detailed data is widely available. These factors and many others can create a complex but competitive supply chain. These supply chains tend to involve more parties and more touchpoints, so they have many spots for the bullwhip effect to take hold.

- Consumer expectations: Meeting customer demands often involves more options, like in-store pickups and direct-from-vendor shipments. These different requirements can increase pressure to have products on-hand and cause the supply chain to branch off into more avenues. Ensuring stock for each option can contribute to overstocking.

- Batched orders: Members of the supply chain might choose to round their orders up or down for simplicity or wait until a certain date to order, which isn’t necessarily an accurate reflection of demand.

- Price fluctuations: Discounts, sales, and other offers affect typical demands and may lead to inaccurate forecasts as buyers attempt to reconcile these sales with their usual forecasting measures.

- Ration gaming: Ration gaming occurs when upstream inventory becomes scarce, so retailers and suppliers order larger quantities and build up their own stocks to ensure they can meet demands, often hurting the entire supply chain in the process. One study found that ration gaming increased the bullwhip effect by 6% to 19%.

- Long lead times: If replenishment product doesn’t reach the seller for a long time, it won’t line up with the demand and help the seller meet customer needs.

How the Bullwhip Effect Impacts the Supply Chain

The impact of the bullwhip effect on supply chain management is significant and includes:

- Storage costs: The cost of overstock isn’t cheap. You must pay for the physical storage space, as well as the inefficiency of storing items that may not be in high demand anymore, and the cost of transporting and selling the items, which could be steep if you have to discount the products to get people to buy them. The bullwhip effect also makes your storage and shipping costs less predictable.

- Increased labor: You need to pay employees to handle, sort, and sell additional items on-hand. Similarly, if a seller runs out of stock, salespeople may need to work harder to locate alternatives or arrange for deliveries later. These labor demands can add up.

- Unmet customer expectations: Running out of a product can cause problems for your reputation and profits. Whether you’re trying to meet the demands of consumers or other supply chain members, being unable to provide products can upset your customers, make you look less reliable, and cause some of them to look for new partners or brands.

- Waste: Depending on the product with which you work, excessive inventory can cause costly waste. Consumable goods, for instance, such as foodstuffs or pharmaceuticals, might expire before you can get rid of your stock, while other items could be withdrawn from sale or replaced by newer versions. These events could reduce the items’ value, increase the number of resources required to sell them, or cost you the price of an item that needs to be thrown away.

How to Control the Bullwhip Effect

1. Increase Transparency Between Suppliers and Customers

The bullwhip amplifies because supply chain members don’t have a full picture of why buyers are increasing demand. Improving visibility across the chain can help everyone see the context of demand changes. Is there an increase in orders because of a discount, seasonal needs, or something else? Members can see what may be causing overreactions and address them before the bullwhip gets out of hand.

Some tools that help here include:

- Electronic Data Interchange (EDI): EDI provides a real-time avenue for exchanging business documents with partners, including suppliers, customers, carriers, and third-party logistics (3PL) providers. EDI systems can automate business processes and streamline a wide range of tasks, such as ordering, sending shipping notices, and invoicing. They replace and standardise many manual processes, such as physical mail, email, and fax. As a result, EDI can speed up communication, increase visibility, and improve relationships with your partners.

- Vendor Managed Inventory (VMI): VMI programs let suppliers receive real-time sales and forecast data from their downstream partners. Combined with pre-determined settings like min/max shelf presence, the data is processed through a machine-learning algorithm to create replenishment recommendations. Using VMI, suppliers no longer have to wait for retailers or distributors to run low or run out before reordering. Instead, they can plan for a new shipment to arrive at the right time to minimise both stockouts and overstocking.

- Internet of Things (IoT): IoT is a booming area of supply chain management. Sensors that connect to your system can provide real-time information about stock counts and product locations. Greater transparency for the company can translate to greater transparency for partners throughout the supply chain. It also comes with other predictive benefits, such as identifying disruptions and maintenance requirements that could affect operations or stock quality.

- Supplier Enablement portals: Even without EDI, suppliers and buyers can communicate in efficient, standardised ways through supplier enablement portals. Portals allow easy integration with EDI solutions, as well as web EDI interfaces, so those who use and don’t use them can work harmoniously with each other’s systems.

2. Start Predicting

Smart predictions are key to better understanding demand changes. With a wide range of intelligent inventory software on the market, you can collect data on just about every business element and turn it into valuable, actionable insights for avoiding the bullwhip effect.

Predictive analytics use advanced algorithms and calculations to interpret historical trends and current events and generate forecasts of future trends. These programs can range from simple to complex, many using artificial intelligence (AI), but all of them rely on high-quality data.

Demand forecasting can be complicated, and predictive analytics can improve this process by pulling in more information. Predictive tools can also help you determine ideal inventory levels and shipping methods. Combining predictive tools like VMI with IoT devices, other data-collection tools, and EDI, means you can significantly improve inventory management. Much of the industry is already getting on board — according to Gartner, over 50% of supply chain organisations will invest in AI and advanced analytics applications by 2024.

3. Encourage Collaboration Between Partners

Different members of the supply chain need to work together to avoid feeling the bullwhip effect. Shared information plays a large role here, allowing different entities to collaborate and see more of the supply chain than just the level they control. Collaboration is especially important in increasingly globalised supply chains, where products may cross borders and go through many different businesses.

Real-time data and end-to-end visibility are essential. Sending purchase orders, for example, is a far cry from strategic collaboration in which you and your partners work to improve forecast accuracy, strengthen relationships, and prevent disruptions before they occur. Aligning your key performance indicators (KPIs) and other performance measures can help everyone stay on the same page. VMI is foundational for this approach, as it puts the necessary information for working together in one place, and leverages EDI to both push and pull inventory and order data between partners.

Robust collaboration is one of the best defenses against the bullwhip effect, which generally comes from disconnected inventory practices.

4. Reduce Lead Times

Long lead times can exacerbate the bullwhip effect, with products arriving far after they’re needed and becoming overstock. Reducing lead times across the board and placing orders when demand is high can mitigate bullwhip issues.

The factors affecting lead times will vary by the needs of your business, but some strategies to shorten lead times include:

- Using trusted, local suppliers: Reducing the distance the product needs to travel can minimise lead times and decrease costs. This option isn’t always viable, but finding reliable, speedy partners is always possible.

- Investing in VMI: Instead of waiting for incoming orders, you can use real-time data to jumpstart replenishment and drastically reduce, or sometimes eliminate, the time shelves spend empty.

- Hiring a logistics manager: With a team member dedicated to logistics, you can improve the level of oversight and attention given to inventory management. Ideally, they can reduce your lead times and help with other elements of the bullwhip effect.

- Reevaluating your shipping methods: If long lead times or inconsistent deliveries are a problem for you, see if you have other shipping options. If one of your partners ships overseas via boat but offers air shipping, see if this option might work for you. Additional costs could be outweighed by the benefits of more predictable inventory.

- Automating manufacturing: On the manufacturing side, you may be able to offer faster lead times with automated equipment and software that helps create a more efficient process.

Lead times should be both short and accurate. Even if you can’t reduce your lead times much, correctly calculating them can help ensure better order fulfillment and less customer disappointment.

5. Minimise or Address Price Fluctuations

If you frequently run promotions or discounts, you may be disrupting typical buying patterns and have more trouble predicting demand. Evaluate your stance on these promotions and see if they might be causing more interruptions than benefits. You may not need to get rid of them altogether but consider minimising them or incorporating them more accurately into your predictions and forecasts.

Implementing the Right Technology

The bullwhip effect can quickly get out of control and hit every part of the supply chain with adverse effects. Visibility and transparency are some of your best resources for fighting the bullwhip effect, and the right platforms can help you find both.

Whether you’re a seller, supplier, 3PL, or another member of the supply chain, you can mitigate the bullwhip effect with TrueCommerce. We’re your one-stop-shop for trading partner communications with solutions across the board, including fully managed EDI services, a comprehensive VMI solution, and next-generation supplier management portals. TrueCommerce helps you connect with every entity of the supply chain so you can better avoid the bullwhip effect and keep your inventory consistent. All of this comes with the 24/7 expertise of our support team.

To learn more about TrueCommerce solutions and how they can help you reduce the bullwhip effect in supply chain management, reach out to a team member today or request a free demo!

About the Author: Ashley Mooney is an eLearning Specialist with more than 15 years of experience educating business users. Since joining TrueCommerce in 2013 as part of the Implementations team and then moving to the eLearning department, Ashley has helped numerous businesses navigate the complexities of EDI systems, giving them the tools they need for EDI success. Ashley lives outside of Pittsburgh, PA, and in her spare time enjoys singing, teaching piano, cheering on the Pittsburgh Penguins, and spending time with her son, Brandon.

Share this post:

Categories

Stay ahead of the competition

Get expert supply chain insights delivered directly to your inbox weekly.