Supply Chain Trends for 2022 and Beyond

March 21, 2022

Supply chains faced a unique set of challenges over the past two years, and the emerging issues have only continued to evolve. Last year, we saw a total reconstruction in how supply chains functioned and a shift towards new technologies. Omnichannel, supply-chain-as-a-service models, B2B eCommerce, and an overhauled workforce are a few of the highlights.

Many of these trends have already been set in motion, creating a new set of table stakes for brand success. Let’s look at what the rest of this year– and beyond – has in store.

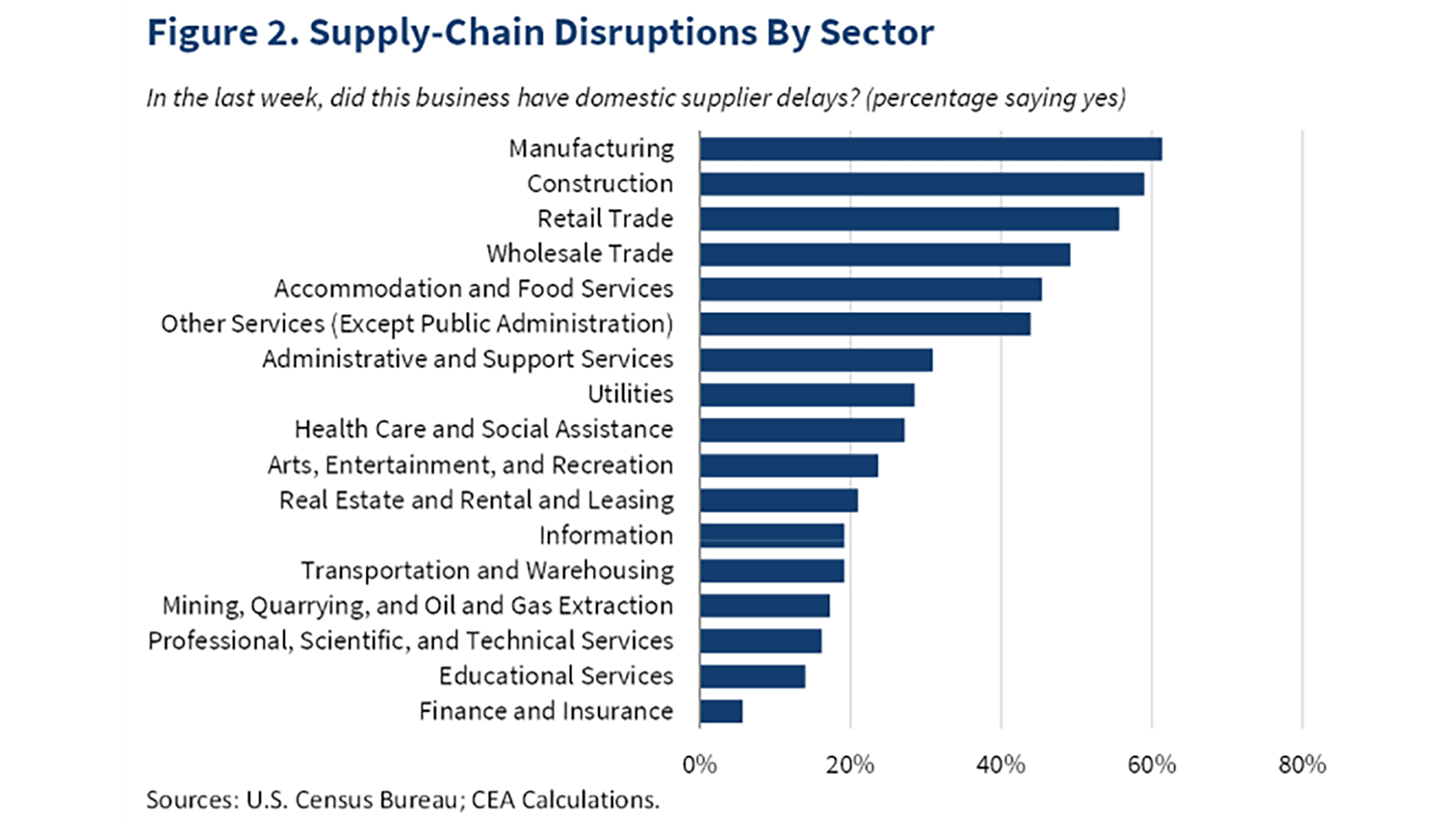

#1: Delays and Disruptions Have Become the Norm

“If you are expecting things to get back to how they were, they aren’t going to. You have to adapt and embrace change to survive and thrive. The good news is that there are products and companies providing services that can help you take and maintain control of your supply chain.” – Josh Wayne, VP, Commerce Products

These delays won’t go away on their own; they’re now a fact of life for suppliers. Manufacturers, distributors, and retailers must be resilient, agile, and ready to combat inevitable delays. For example, we’ve all learned by now that depending on one supplier is bound to cause issues. Moving forwards, brands will need a new strategy and a more diverse supply chain to mitigate unforeseen breaks in the supply chain.

Setting up alternate suppliers and logistics methods to fall back on when something goes wrong is crucial. So is keeping better track of stock, both in warehouses and stores, as well as in-transit.

Almost every company has felt the impact of this problem. Businesses that can rise above it will likely generate greater profits and earn customer loyalty.

#2: Brands Invest in Automated Supply Chain Technology

“Things are becoming faster in all aspects of the supply chain, from providing real-time data on product and inventory, to multichannel sales, to digitisation across the supply chain, often using tools like AI and automation. Businesses are becoming smarter but doing that through new applications and tools that help improve their processes and learn more about their consumers.” – Ryan Tierney, VP Product Management

With increased uncertainty in supply chains, companies are choosing to invest more and more into digital solutions. Using pen and paper is no longer an efficient way to run a business. Automation can streamline weeks of manual work, freeing up more time and money to invest elsewhere. But even more importantly, automated solutions let businesses respond to changes quickly, and get valuable information in near real time. Here are a few ways businesses are leveraging automation in 2022:

- Distributors and retailers are using Supplier Enablement Platforms to diversify their supplier bases, while digitising the order process for faster communication.

- eCommerce brands are using integrations to send orders directly from their listings on Amazon and other marketplaces to their ERPs, which can send back-order status updates and accurate inventory levels.

- Businesses of all sizes are investing in EDI software, which can relay order, shipping, and invoice documents in moments, and automatically deliver that data to their ERP system.

#3: Increasing Importance of Real-Time Inventory Visibility

“There can’t be any surprises in your supply chain anymore. You must have visibility to understand when you will get product and when you can deliver it to your customers. If you don’t have that, you won’t grow your business.” – Josh Wayne, VP, Commerce Products

When it comes to supply chain visibility, deep insight inventory availability is something a top priority–and for good reason. Customers value transparency during the buying and shipping process, whether they’re other businesses, or end consumers. But between delays and disruptions, changing consumer behaviors, and with brands opting to diversify their supply chain and expand into omnichannel markets, true visibility is more difficult to achieve.

Digital solutions like EDI can provide visibility into product movements across the supply chain. But for procurement professionals, Vendor Managed Inventory (VMI) software offers a way to not only see inventory levels but use that data to keep shelves stocked.

Share this post:

Categories

Stay ahead of the competition

Get expert supply chain insights delivered directly to your inbox weekly.