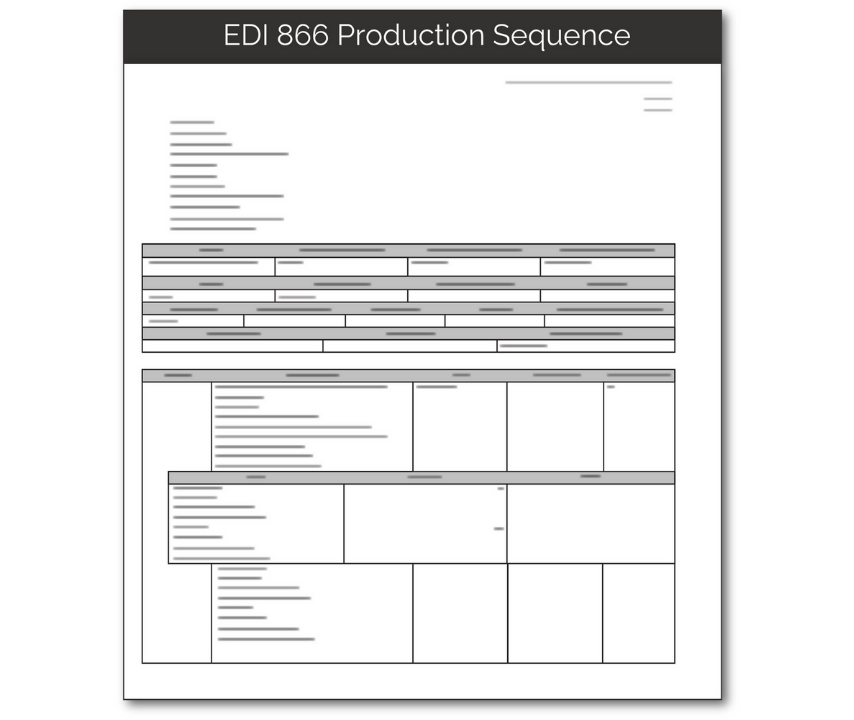

EDI 866

Production Sequence

What is an EDI 866?

EDI 866 is an electronic transaction that replaces the need for a paper Production Sequence. This document is usually sent by a receiver, such as a warehouse or manufacturer to request a specific receiving or unloading order. For example, if multiple shipments are being sent, the receiver may want Shipment B before Shipment A, and may also want Pallet or Carton X to be unloaded before Pallet or Carton Y.

EDI 866 documents follow the x12 format set by the American National Standards Institute (ANSI), a not-for-profit organization that regulates EDI formats in the U.S.

What are the Essential Components of EDI 866?

EDI 866 must include several key elements relating to an order or orders set for shipping. These include, but are not limited to:

- Shipper, carrier, and receiver contact information

- Order or shipment numbers

- Ship-to location(s)

- Request for order of shipment arrival

- Request for unloading sequence, also called an order of removal

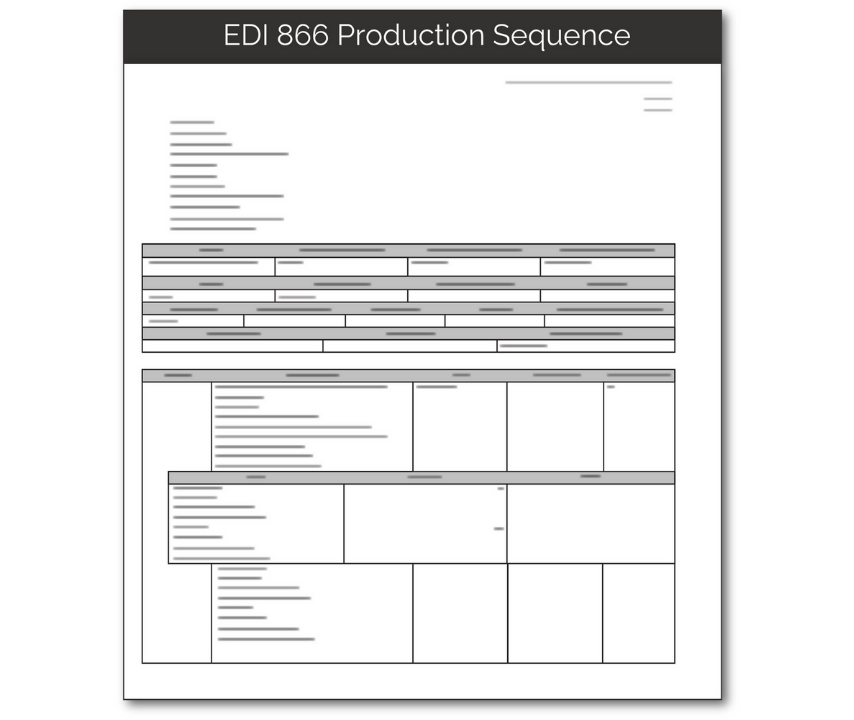

How do I Use EDI 866?

EDI 866 is used by a warehouse or other receiving business when they are expecting multiple shipments, or multiple orders in one shipment. This document does not need to be triggered by the receipt of another EDI transaction, but is instead sent at the receiver’s discretion, based on their business needs.

Within EDI 866, the receiver can ask for certain shipments to arrive first/second/last, and indicate an unloading methodology, which may impact load sequences on the carrier’s end. This document can be used for both single-location and multi-location shipments. However, it does not authorize materials or labor, or any other resources.

After receiving EDI 866, the shipper and/or carrier will usually confirm receipt with an EDI 997 Functional Acknowledgement.

What are the Benefits of EDI 866?

By specifying an order for arrival and unloading, receiving warehouses and assembly lines can optimize their unloading process and ensure the right products are received at the right time in the right order. This can help maximize production efficiency, while minimizing loading dock confusion, discussion, and delays.

Automating EDI 866 saves time and prevents communication errors by eliminating the need for manual data input. Additionally, sensitive business details listed on EDI 866 are more protected than on a paper Production Sequence, thanks to security protocols, encryption, and other security methods employed by EDI solution providers.