How nVent Electrified Their Fulfillment Process with VMI

March 17, 2021

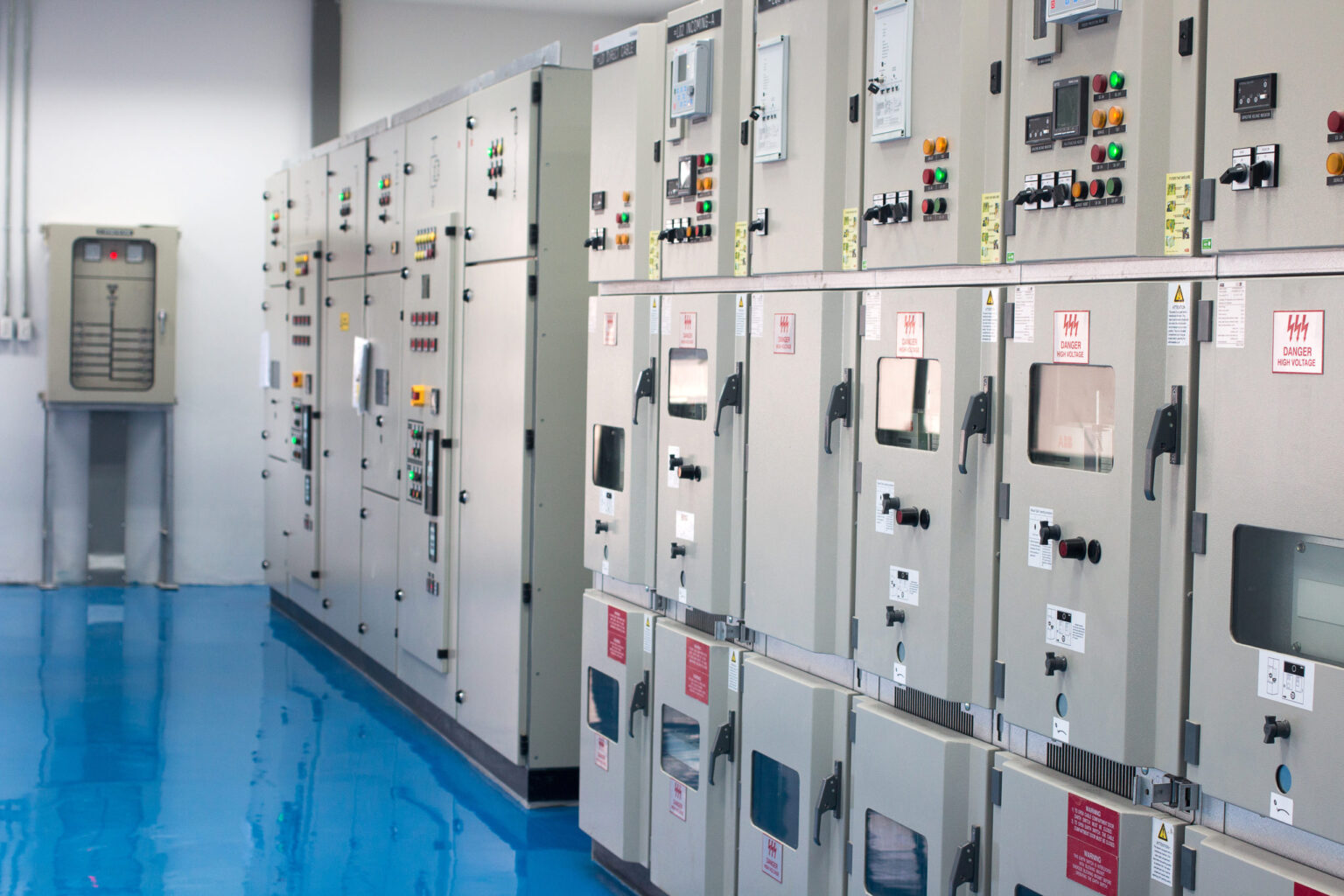

nVent’s products have roots that go back to 1903, when the Electric Railway Improvement Company (ERICO) was founded to supply technical equipment to the railway and mining industries. Today, nVent offers a wide range of high-performance electrical equipment under brands like CADDY, ERICO, HOFFMAN, RAYCHEM, SCHROFF, and TRACER. nVent products are trusted for applications like data center construction, electrical safety, fuel leak detection, and power distribution.

Shipping high-tech equipment like heat sensors, operator consoles, and terminal boards to distributors is no walk in the park. Before nVent began working with TrueCommerce, the company would ship orders as they came in from distributors. This led to the company spending more on freight than was necessary, since most orders were less-than-truckload (LTL). Products would shift around in trucks since there was more empty space, as well. As a result, nVent dealt with a high rate of damaged product, which was expensive to replace.

From Reactive to Proactive Fulfillment

At a certain point, the nVent team decided they needed to move away from a reactive fulfillment system to a proactive one. Senior VMI Analyst & Program Specialist Kirsten Gilmer said, “Putting more product in trucks and reducing the number of shipments was the simplest solution. But our distributors had become accustomed to creating orders several times a week. We knew what we had to do, but we didn’t know the best way to go about it.”

In other words, if nVent could view its distributors’ inventory in real time instead of waiting for them to place orders, it could create optimized purchase order suggestions and consolidate shipments. That’s exactly what the company found with the TrueCommerce Datalliance vendor-managed inventory (VMI) system.

Getting Started with VMI

So, what is VMI? Vendor Managed Inventory is a replenishment model that allows a manufacturer to receive inventory data in real time from its distributors. The platform uses advanced algorithms in concert with this data to optimize and automate purchase orders based on agreed-upon metrics like minimum and maximum stock levels. The system can also use advanced data to fill trucks and improve order loading to keep products safe and secure.

VMI lets vendors like nVent maximize sales and inventory turnover while minimizing stockouts, without forcing distributors to overstock. For example, a VMI solution can send products where they are needed most across its network of distributors, which can help the company take advantage of store-level promotions and local product popularity or manage shifts in demand during a crisis or recession. VMI can also offer collaborative replenishment solutions so that the manufacturer, distribution centers, and retail stores all work together to optimize the supply chain.

Fuller Trucks and More Sales

Another benefit of VMI: fewer, fuller trucks on the road. For nVent, that translated not only to savings on shipping costs, but also less damage to products in transit. Dealing with damaged returns can be costly, especially when the products are high-tech and high value. If the end customer was counting on a particular product to come in on time, a damaged product can set construction schedules back, and that reflects poorly on the brand.

“Before VMI, we didn’t know how much inventory a distributor had,” said Gilmer. “Now, we can see every SKU being managed by our VMI program from TrueCommerce Datalliance. It’s like being inside a distributor’s warehouse and helping them order the inventory they need. Not only that, but the data also enables us to build fuller trucks as we know how much time we have before a distributor runs out. Fuller trucks help solve the problem of products being damaged during transit.”

With VMI, nVent’s distributors receive the right amount of product in less shipments overall. Truck building capabilities make sure pallets are loaded and stacked in the right order and sensitive products are packed safely, and that’s a win for the company.

So, what was the result after nVent implemented the TrueCommerce Datalliance VMI program? The company analyzed operations at 61 distributors one year after implementation to find out. With better control over sending product exactly where and when it’s needed, nVent saw out-of-stocks decrease by 18% and item availability increase by 16%. Ultimately, that means its distributors were able to satisfy more customers. In turn, sales also increased by 28%.

nVent Enjoys Better Fulfillment Through Automated VMI

With the TrueCommerce VMI program, nVent was able to rise above reactive fulfillment to accurately forecast shipments based on real-time stock data. No longer did it need to wait for distributors to place spontaneous orders. Automated VMI further reduced human errors like ordering too late or ordering too often and wasting space on a truck. All of this supports nVent in its mission to connect and protect its customers through dependable electronic equipment.

Get the Full Story

Check out the nVent VMI success story to learn more about how nVent optimized shipments and boosted profits

About The Author: Scott Kleinert is a global sales executive with more than 25 years of experience in supply chain strategy development. He is currently responsible for TrueCommerce’s collaborative management service offering with specific expertise in the consumer goods and retail industries. Scott leads the team that initiates and develops the TrueCommerce vendor managed relationships as well as cementing the value associated with these collaborative initiatives. Scott lives in South Carolina, taking advantage of all that coastal living offers.

Share this post:

Stay ahead of the competition

Get expert supply chain insights delivered directly to your inbox weekly.