How to Create a More Resilient Supply Chain

November 22, 2022

Supply chain resiliency has always been an important component of business operations. However, the events of the past few years have brought resilience to the forefront of business strategy. Not only have we endured a pandemic that set off countless closures, delays, and other supply chain issues. In today’s markets, change has become a constant across regions and sales channels—meaning that resilience is non-negotiable.

In a 2020 survey, nearly 90% of supply chain professionals said they planned to invest in resiliency. Modern-day supply chains are complex and globally dispersed. Without a proper plan, supply chain disruptions in one area can easily affect others, creating a chain reaction that ultimately impacts operations, sales, customer satisfaction, and many other components of doing business.

With so many different players, strengthening a supply chain can seem like an unwieldy task. It isn’t simple, but the right approach and technology can help, and the competitive advantages of creating a resilient supply chain are too great to ignore.

What Is Supply Chain Resilience?

Supply chain resilience refers to a supply chain’s ability to withstand disruption, mitigate its effects, and grow through it. A strong supply chain should be able to limit the impact of events such as:

- Weather: Weather events like floods, hurricanes, and wildfires can take major contributors out of commission. Consider large distribution centers or manufacturing plants that might be destroyed during these events.

- Geopolitical events and policies: Political upheaval or decisions can impact a company’s ability to do business in certain areas. For example, increased import or export taxes or banned products could affect sales or access to supplies.

- Economic conditions: As the economy ebbs and flows, it affects the supply chain. The cost of labor or supplies might increase, creating financial challenges or availability problems.

- Automation failures: Technology and machinery keep many businesses moving. Failure here could bring operations to a halt.

How Does Supply Chain Resilience Work?

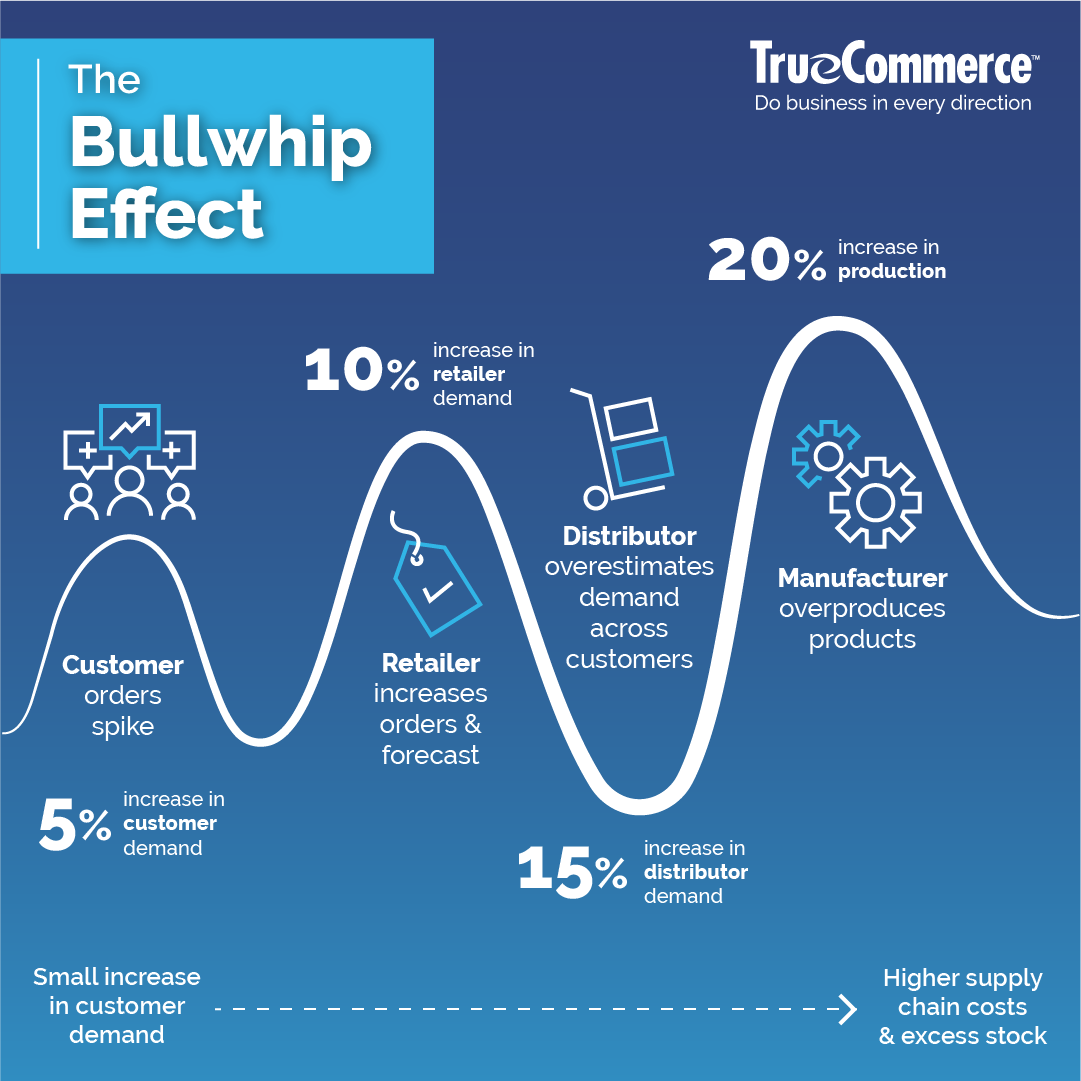

Creating a resilient supply chain depends on many different factors. Although it might call for clear-cut tasks like diversifying suppliers and centralizing data, it also asks you to redefine how you approach unexpected changes in supply and demand. These range from supply chain disruptions like pandemics, to chain reactions like the bullwhip effect, to large-scale economic changes like recessions.

You may need to set up proactive data analysis, eliminate silos, and establish protocols for quick responses and communications. To strengthen your supply chain, you’ll need to take a close look at many different areas of business operations, including your technical solutions and your company’s perspective on decision-making.

Technical solutions encompass the tools you use to improve supply chain resilience, such as data management platforms and analytics. One of the most important elements is visibility. If you have many disconnected partners, your data — such as inventory counts and tracking information — isn’t in sync in real time. You don’t know where your suppliers are at in the process and might be blissfully unaware of problems or slowdowns. Centralizing your data increases visibility across your supply chain.

Another vital part of supply chain optimization is how you respond to interruptions. You’ll need to have a range of protocols and analyses in place to stay proactive and respond to problems appropriately. For example, you’ll need to assess the risk of every supplier in your network and balance factors like location, performance, and the diversification of the whole supply chain. Established plans and processes can help improve the quality and speed of your responses.

Benefits of a Resilient Supply Chain

A resilient supply chain is critical for a sustainable business that can withstand problems. One study found that, when compared to performance during stable periods, performance during crisis periods had nearly three times the impact on long-term success. In other words, resilient businesses were more likely to outperform non-resilient businesses even after the disruption.

Some of the positive impacts of supply chain resilience include:

- Efficiency improvements: Resilient supply chains can quickly switch gears and make changes to prevent disruptions before they even occur. They can eliminate downtime and risk, leaving more resources for investments in business growth and improvements.

- Productivity boosts: When they spend less time tracking down information about shipments or responding to problems, employees have more time to focus on more valuable tasks.

- Less risk: A supply chain is a major vulnerability for most businesses and strengthening it can help minimize risk.

If you can stay productive and profitable amidst disruption, you have a major edge over competitors who might not be able to meet demand. It presents an opportunity to earn more customers and get out ahead.

How to Create a Resilient Supply Chain

If you’re looking to strengthen your supply chain, you’ll need to create a clear vision and develop a plan. Below are some steps for an optimized supply chain that can help you decrease risk and improve operations.

How to Build a Responsive Supply Chain

1. Create Your Response Team

Start by designating a team of experts who can get together and make decisions about responding to interruptions. They will oversee establishing procedures and response plans and execute them as needed. They’ll need a strong understanding of the entire global supply chain and different elements of the business.

2. Develop a Communication Plan

When disruptions occur, they impact everyone. Create a plan for communicating these changes with relevant stakeholders, employees, and customers. Remember to keep these messages transparent and consistent, so everyone is on the same page.

3. Audit Your Supply Chain Risk

Conduct a supply chain audit to assess your risk for disruption. Look for:

- Contingency: Start by creating a comprehensive map of your partners, such as the locations of manufacturing plants, distribution centers, and logistics partners. Identify your key suppliers and any issues, such as a large grouping of distributors in one area. Look for alternative options in case one supplier becomes compromised. Consider how many steps are involved in working with each partner and whether onshore locations might provide more resilience.

- Performance: You can assess future risk by monitoring how well your partners perform. Track their accuracy, product quality, timeliness, and other metrics that can tell you how well they’re meeting your needs. If they appear unreliable, establish alternative options.

- Visibility: Make sure you have visibility into your products internally and through each supplier. You should be able to account for orders and items without any hassle and access up-to-date shipping information.

- Prioritization: In the event of a disruption, consider how you will prioritize your most important buyers, such as those with high-revenue purchases.

4. Create a Plan for Low Supply

Develop criteria to guide decision-making when supplies run low. This might involve substituting one material for another or switching suppliers. Implement buffer capacity to prevent these situations and consider alternative manufacturing practices if needed.

5. Watch Your Finances

Monitor finances carefully. Consider increasing days payable to suppliers, which allows you to maintain your cash position for longer and minimize inventory costs and days receivable. Create a plan for adjusting costs accordingly to manage limited supplies.

6. Create Long-Term Goals

Consider where you can add resiliency through larger projects, such as:

- Breaking down silos.

- Improving end-to-end visibility.

- Implementing agile supply chain strategies.

- Updating your technology for better integrations.

- Researching artificial intelligence or machine learning solutions to predict interruptions.

- Increasing staffing flexibility through automation or changes to hiring practices.

Strengthen Your Supply Chain with TrueCommerce

A comprehensive technology solution can help with many of these tasks. TrueCommerce is a wide-reaching platform for electronic data interchange (EDI), which underpins most supply chain communications. With an array of tools and integrations to increase visibility, manage data, and communicate with partners, TrueCommerce can help you boost supply chain resiliency and stay prepared for what’s to come. Whether you have a few partners or a hundred, we can help you optimize your network for a dependable, flexible supply chain.

Reach out to a representative today to learn how TrueCommerce can help you build a resilient supply chain for the future.

About the Author: Ivy Davis is a Demand Generation Manager at TrueCommerce who has spent years delving into the challenges faced by manufacturers and retailers across industries. She focuses on providing supply chain insights and actionable advice through webinars, blogs and thought leadership interviews. She believes that empowering decision makers with knowledge drives them to make thoughtful decisions about supply chain technology and improve their overall business strategy. After a long day’s work, Ivy enjoys cooking with her two kids and gardening outside.

Share this post:

Stay ahead of the competition

Get expert supply chain insights delivered directly to your inbox weekly.