EV Fever or Running on Empty?

August 3, 2022

The electric vehicle (EV) boom has the potential to disrupt and transform the entire automotive industry. According to an article from MarketWach, “Declining prices and increasing availability of electric vehicles, or EVs; the potential for technology breakthroughs that offer a cheaper, longer-lasting, and faster-to-recharge battery; strides in EV infrastructure, and ‘green friendly’ government initiatives taking root in the U.S. and elsewhere show the likely path.”

In early 2021, Ford announced a $29 Billion commitment to electric and self-driving cars through 2025, making them an early pioneer in electrification that will produce 15 new battery-electric vehicles (Car and Driver). “We’re not going to cede the future to anyone [when it comes to electric vehicles]”, Ford CEO, Jim Farley, told CNBC.

Meanwhile, the German automaker, Volkswagen, stated that it would reduce the cost of producing its batteries by 50 percent, build multiple battery factories across the globe, and expand its network of charging stations. “Our transformation will be fast; it will be unprecedented,” said Volkswagen Group CEO, Herbert Diess. “The transformation will be bigger than anything the industry has seen in the last century.” Herbert Diess. “The transformation will be bigger than anything the industry has seen in the last century.”

Other major auto manufacturers, including Toyota, have also shifted focus toward battery-powered vehicles. “Toyota would consider production at an existing or new factory in the U.S. in response to a sustained increase in American consumers’ appetite for battery-powered vehicles,” stated Bob Carter, EVP sales in the U.S.

To help drive the U.S. EV evolution, the Biden administration allocated approximately $174 Billion towards EV initiatives, including installing charging stations and providing tax incentives for EV buyers. This has since been enhanced with the enactment of a $1 trillion bipartisan infrastructure law, which includes more than $7 billion to bolster the country’s battery supply chain and a $3.1 billion plan to boost domestic manufacturing of batteries, “in a broader effort to shift the country away from gas-powered cars to electric vehicles.”

Given all these optimistic and forward-thinking statements, let’s examine some of the primary barriers to entry.

Customer Adoption & Market Anticipation

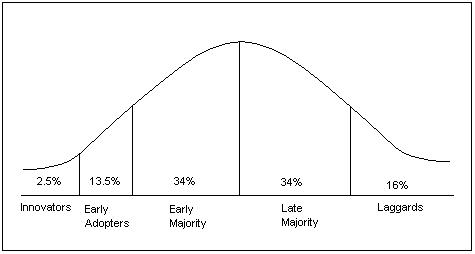

One primary aspect to consider is the rate of customer adoption. According to the Diffusion of Innovation Theory, only about 16% of the general population will adopt an innovation in its early stages. These individuals typically have substantial financial resources and technical knowledge but can also help to facilitate adoption on a larger scale.

The concept of the electric vehicle has been around for decades. Still, the most notable turning points occurred in 1997 when the Toyota Prius was introduced and in 2006 when Tesla Motors started producing a luxury electric sports car. This industry has since exploded, spurred on by technological advancements and the need for more sustainable transportation.

To meet the growing interest of the EV market, emerging EV original equipment manufacturers (OEMs) are seeking to create a unique buying experience that is tailored to fit customer preferences with augmented reality and interactive studios that simulate the driving experience.

A great example of an EV company filling the anticipation of a market need is Arcimoto out of Portland, OR. Their FUV (Fun Utility Vehicle) is all about the joy of driving on the open road, creating a vision for reducing congestion and contributing to a green environment. Their line-up of products addresses last-mile delivery, emergency response, and recreational use.

Price & Availability

Electric Vehicles are currently depicted as fun or sensible vehicles when making short commutes, but will the emerging EV OEM market be sustainable to serve the mid-market and luxury categories? According to Bloomberg, a consumer reported spending 38,800 yuan ($6,065) on their Hongguang Mini EV and 320,000 yuan ($49,000) on their Volvo XC60. With its price point, the Hongguang Mini EV was recently reported to be outselling Tesla models two to one, but this EV is only available in China, making it less accessible to the global market.

The Lucid Air, which has a promising 406-mile range and 480 horsepower, has a starting price of $69,900 (after the $7,500 U.S. Fed Tax credit). For this price, it also boasts a first-class cabin experience, establishing its role in the luxury EV market.

While there are various other EV models available, finding a balance between price, demand, and availability appears to be one of the main struggles among these OEMs.

Range Anxiety & Charging Times

As EV adoption increases, so will the need for charging stations at highway rest stops, major city centers, and work. According to Car Magazine UK, the Mercedes EQS 450+ is listed as the electric car with the longest range currently on sale, with a range of 453 miles. This range is a little more than half the distance to cross the state of Texas, and with fewer charging stations available, customers will need meticulous planning for longer road trips. Additionally, drivers will likely have to keep to the highways instead of the scenic countryside routes where charging stations are scarce, if not obsolete.

The federal government has instituted a mandate for OEMs to offer a minimum of an 8-Year/100,000-mile warranty on batteries, with some manufacturers providing more protection. According to Consumer Reports, the expected life span of an EV battery pack is about 200,000 miles; double the miles that are federally mandated to cover. Despite this fact, a recent study found that 46% of consumers considering an EV viewed the average battery life as 65,000 miles or less. However, according to Consumer Reports, the expected life span of an EV battery pack is about 200,000 miles. Cox Automotive stated that 46% of consumers considering an EV viewed the average battery life as 65,000 miles or less, making them hesitant to purchase.

Even with this reassurance, a battery is one of the most expensive electric vehicle components, with the average cost to replace one being around $5,500. Additionally, a 66 kWh battery for a Chevrolet Bolt EV was recently reported at about $16,000, and that is not including the cost of labor for installation. Still, some EV batteries cost as little as $2,500 to replace, while others can be upwards of $20,000.

Even with this reassurance, a battery is one of the most expensive electric vehicle components, with the average cost to replace one being around $5,500. Additionally, a 66 kWh battery for a Chevrolet Bolt EV was recently reported at about $16,000, and that is not including the cost of labor for installation. Still, some EV batteries cost as little as $2,500 to replace, while others can be upwards of $20,000.

Along with concerns over battery life, there is concern about the amount of time it takes to charge an EV fully. The average time it takes to fill a mid-sized SUV with gas is approximately 4 minutes. However, the amount of time it takes to fully charge an electric vehicle varies wildly.

According to Pod Point Counter, the time range for fully charging an EV from empty to full can be anywhere between 40 minutes and 21 hours, depending on the battery capacity and charging rate. “A typical electric car (60kWh battery) takes just under 8 hours to charge from empty to full with a 7kW charging point.”

7-Eleven is stepping up to install at least 500 Direct Current Fast Charging (DCFC) ports at 250 select convenience stores in the United States and Canada by the end of 2022, according to an article from Convenience Store News. This initiative should help to pave the way for more confidence traveling cross-country in an EV.

Rethinking the Global Supply Chain

The global pandemic turned the automotive supply chain upside down. Even now, traditional OEMs continue to struggle with JIT/JIS (Just-in-time/Just-in-sequence) as the timely delivery of critical automotive parts and components is more unpredictable than before the COVID pandemic. According to CNBC, chip shortages are expected to cost automakers $210 Billion in revenue in 2021.

As OEMs experience production delays — Tier 1 and Tier 2 suppliers are experiencing the pinch on capital costs and lack of visibility to payment, acknowledgment, and closing the loop on returns and spills. We analyzed many of these challenges in the blog Building a Better, More Resilient Automotive Supply Chain, noting that integration and automation to align the supply chain to production are key to success.

According to the Benchmark Mineral Intelligence, sighted in the Washington Post, “China dominates battery production, with 93 ‘gigafactories’ that manufacture lithium-ion battery cells, versus four in the United States.” For an EV start-up, where every penny counts, it will be challenging to compete against the behemoth automakers to meet inventory requirements while managing cash flow.

The Future of EV & the Automotive Supply Chain

EV adoption is on the rise, but it still has a long way to go. This particular supply chain industry demonstrates the need for best practices and enabling integration technologies to drive and manage global businesses. As we adjust to post-pandemic levels, it is crucial that we embrace digital transformation projects that can adapt to changing conditions and improve visibility within operations. The EV movement is picking up speed. Will you be left running on empty?

TrueCommerce offers automotive OEMs, suppliers, 3/4PLs, and third-party finishers an integrated supply chain management solution that delivers real-time visibility and value. Contact us to learn more and discover the impact of automation technology on the EV automotive supply chain.

About the Author: Shawn McEwen, regional vice president of automotive and industrial manufacturing at TrueCommerce, is a business leader who enjoys building bridges within Automotive Supply Chain & IoT segments. He provides turn-key cloud B2B Managed Services that allows organizations to integrate and exchange critical business documents between trading partners. His proven ability to collaborate across all lines of business with a passion for sparking strategic discussions in the boardroom creates value and builds customer relationships.

Share this post:

Stay ahead of the competition

Get expert supply chain insights delivered directly to your inbox weekly.