Valentine’s Day: Insights into the Greeting Card Supply Chain from Lovepop

February 11, 2022

Valentine’s Day. It’s a day to celebrate romance, and for retailers, that means record sales of chocolates, teddy bears, jewelry, and of course, Valentine’s Day Cards. This year, consumers are expected to spend upwards of $1 billion on Valentine’s Day greeting cards, according to data from the National Retail Federation. For a market worth $7.3 billion in 2021, that’s a significant amount of business packed into one holiday!

So how does the greeting card industry prepare for one of their biggest sales events of the year? We turned to the experts to learn more about the unique supply chain that powers every “be mine” card-opening moment: Lovepop.

Yes, Lovepop! The pop-up card sensation made headlines in 2015 after appearing on Shark Tank and wowing Kevin O’Leary with their uniquely beautiful Slicegamiâ„¢ cards. By 2017, Lovepop’s business had increased more than 20X, and it keeps growing at a rapid pace (+44% YoY in 2020, if you’re interested). In addition to cards, the brand also makes everything from pop-up paper flower bouquets to ornaments, wreathes, and even sculptures.

I had the pleasure of speaking with Lovepop’s Senior Director of Internal Systems, Dan Nephew, a few weeks ago. He shed light on how Lovepop manages a massive greeting card supply chain and conquers love every year on February 14th.

The Greeting Card Supply Chain

Before we dive into Valentine’s Day preparation, it’s important to understand how a Lovepop card goes from an idea to a design, to a product, to customers. Dan broke it down into the basics, saying, “We have a really dynamic design team that handles everything from concept, to licensing, to prototyping and quality checks.” Those quality checks ensure that every Lovepop card actually does POP. Then the card undergoes shipping tests, because the products need to survive both bulk deliveries and single mailers to customers.

From there, marketing and operations take over. While marketing figures out what to promote, and how, Dan and the operations team ensure a frictionless entry into the supply chain process. How? Well, Dan says it comes down to flexibility and agility.

“One of the things that makes us unique is that our supply chain is very fast. We’re pretty nimble, we don’t have a lot of layers, and our process is flexible. That allows us to go from concept to availability in a short time.”

Lovepop cards are sold both online and in brick-and-mortar retail locations, with a blend of everyday staples and highly seasonal greetings that creates a complicated supply chain. Dan laughingly commented that seasonality “doesn’t make for a smooth supply chain. It requires a lot of expertise on both the systems and operations sides to make it work.”

For example, Lovepop uses vendor managed inventory (VMI) software to keep store locations stocked with the perfect cards for every occasion. Because VMI leverages real-time sales data and automation to create replenishment orders, it is much faster than traditional store ordering methods.

With VMI running in the background, Lovepop can operate on just a one-week lead time. In contrast, traditional replenishment models usually operate about two to three weeks out. Dan explained, “In a non-VMI setup, the stores have to do their forecasting, figure out what they want to plan for, and then send the orders over to get replenished. It takes a while. With VMI, you cut all of that out, so we can just react.”

Valentine’s Day Preparation

Whether couples are dining out or staying in, many of us will find ourselves getting “date-ready” with the perfect outfit, hairstyle, and makeup look. Well, Lovepop’s been getting ready for its big date for quite a while.

The brand’s team of expert data scientists play a key role in forecasting, with numerous models that help Lovepop understand market trends. Historical data across product types and attributes help the design and marketing teams make strategic decisions. But even this is more challenging in the greeting card space because most of the products change year after year. After all, who wants to receive the same Valentine two years running?

Dan said that the brand tries to get started as early as possible, often months in advance. But some cards didn’t hit production until what seemed like the last minute. “We had products for this Valentine’s Day that weren’t ready to be manufactured and sent until January. And that’s both products that needed small design tweaks, and late ideas that we wanted to add in.”

How can Lovepop operate a supply chain on the fly, even for one of its biggest events? Dan used the analogy of a two-way door to explain it.

“One-way doors are hard to go back through, but two-way doors are easy. We try to have a lot of two-way doors in our supply chain. That way, if something needs to change at any step in the process, it can. If a card isn’t selling the way we predicted, we can switch and manufacture more of another card.”

The ability to turn their supply chain on a dime is critical to Lovepop’s success, but it requires the right systems in place at all times. Dan says the goal is to have supply chain software that doesn’t have to be thought about. He said, “We don’t want our systems to hinder the creativity and engineering on the front end of the business. Our goal is to be frictionless.”

“If we have a great idea and we design the heck out of it, we don’t want to go back and say the idea won’t work because we can’t handle the order volume or can’t manage inventory at that many locations. That’s what the VMI and EDI systems from TrueCommerce allow us to do.”

While Lovepop starts designing products for Valentine’s Day in advance, Dan and his team don’t have to confirm inventory shipments until the day they need to ship. “We don’t plan a location’s specific inventory till we have to,” he explained, “We ship to stores every week, and we don’t have a lot of back-room space. Being able to make replenishment decisions quickly is key to keeping our supply chain moving at this rapid pace.”

Love, Lovepop

It’s not just Lovepop’s supply chain that’s unique—it’s the people that truly make the company special, according to Dan. He told me, “There’s a hunger within our people to succeed, and our leaders give everybody the autonomy to go after new ideas.”

That hunger has built up a catalogue spanning thousands of products, sold online and in stores across not just the United States, but dozens of countries around the world. It’s what drives Dan and his team to build a nimble, efficient supply chain. And, I imagine, it’s what makes each product that Lovepop calls a “magical moment.”

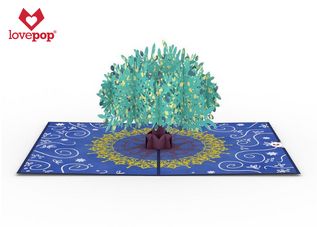

I had to ask Dan what his favorite Lovepop product was. “The Olive Tree Card,” he told me. Why? “It was the first card I was given when I started.”

Happy Valentine’s Day to Dan Nephew, the entire Lovepop team, and you!

About the Author: Lindsey McGee is a Marketing Content Writer specializing in supply chain strategy, thought leadership, and education. As part of the Marketing team at TrueCommerce, Lindsey strives to provide thoughtful, accessible information to help business owners grow and manage their operations. Lindsey lives in Pittsburgh with her husband, Cody, and rescue pets, Delta, Bahn, and Izzie.

Share this post:

Stay ahead of the competition

Get expert supply chain insights delivered directly to your inbox weekly.